IMAP Ammonia+™

Augment your main ammonia business with on-demand methanol production IMAP Ammonia+™ design employs ...

Topsoe’s integrated methanol and ammonia process (IMAP™) gives you the flexibility you need to get ahead and stay there.

Imagine a plant that could deliver what the market wants most, whenever the market wants it. No more being locked into a single product, with its ups and downs. No more missing out on opportunities to meet needs outside your main product. And no more having to build two plants to make more than just ammonia or just methanol.

Equally suitable for revamp and grassroots projects and no matter whether you operate a dedicated ammonia plant, methanol plant or fertilizer complex, our co-production plant designs give you unprecedented agility, protection from market fluctuations and profit-making potential.

Topsoe’s IMAP™ (Integrated Methanol and Ammonia Production) technologies and Topsoe’s latest innovative syngas hub solution for large scale facilities, the cost effective SynCOR Plus™, enables the facility to produce multiple products without the prohibitive cost of installing and operating a second plant. Both technology concepts take advantage of the catalysts and technology used making single product facilities

The IMAP™ technology covers combined capacity of ammonia and methanol up to 3.200 MTPD and SynCOR Plus™ up to 10.000 MTPD. Both concepts also include the possibility to convert the ammonia into urea.

A Topsoe co-production facility offers numerous advantages over two standalone plants, including:

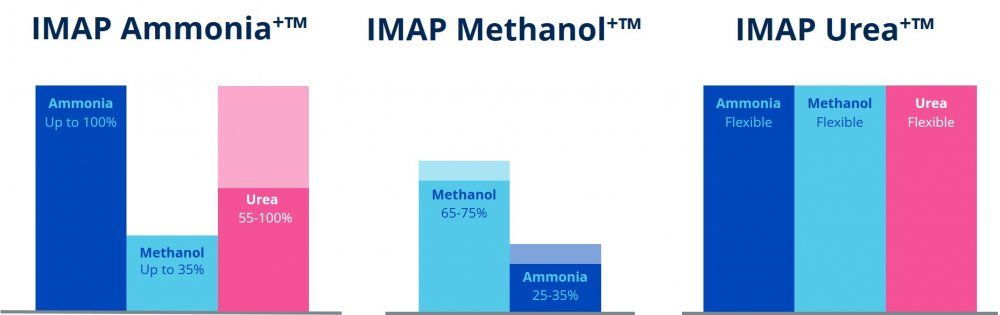

Choose the product mix and corresponding IMAP™ solution that makes most sense for your plant.

Our IMAP™ technology enables any facility to produce multiple products without the often prohibitive cost of installing and operating a second plant. Comprising three separate process designs – IMAP Ammonia+™, IMAP Methanol+™, and IMAP Urea+™ – our IMAP™ portfolio can add significantly to your bottom line by enabling you to meet multiple and changing market needs as they arise.

IMAP Ammonia+™ is an ammonia plant with an efficient add-on methanol section. The concept can be designed to produce up to 100 % ammonia and up to 35 % methanol or any combination in this range while observing a combined total production of 100%. It can be made for a grass root facility or as a revamp of an existing ammonia plant.

IMAP Methanol+™ is a very cost efficient co-production design producing 65-75% methanol and 25-35% ammonia. The actual product split is decided by the feed gas composition and the clients need.

IMAP Urea+™ is an ammonia plant with an efficient methanol section which can be designed for full flexibility between ammonia, urea and methanol. The main difference between IMAP Ammonia+™ and IMAP Urea+™ is use of enriched air as oxygen/nitrogen feed which provides the high product flexibility.

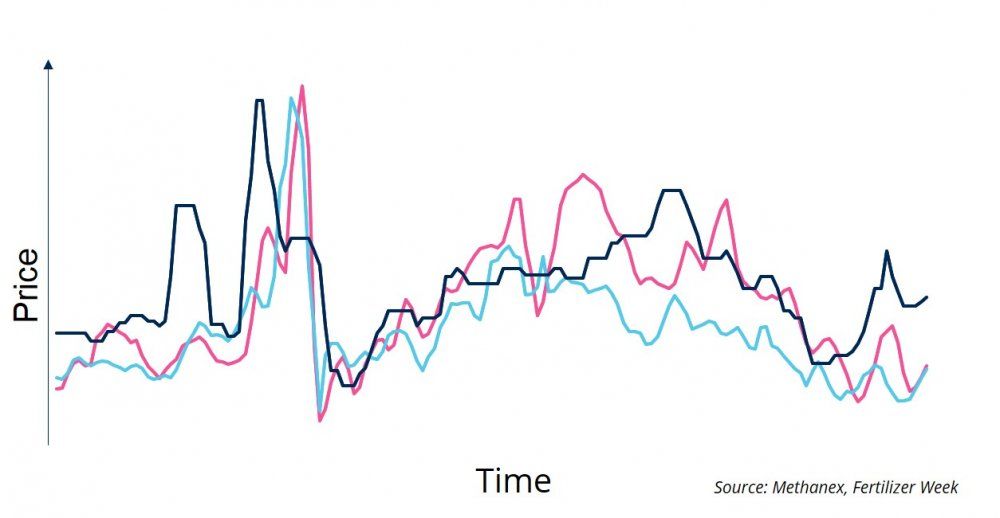

Multiple products offer flexibility toward price fluctuations.

As a plant owner, you’ll want to decide just how much flexibility you want right from the start, to make sure your investment costs are aligned with your needs. In addition to our three basic IMAP™ process designs, we can tailor an IMAP™ solution to meet the specifics of your business and technical needs. If you’re not sure which IMAP™ process design would best suit your plant, we are happy to conduct the feasibility studies you’ll need to make the right decision.

SynCOR Plus™ is a syngas hub concept where SynCOR™ is used as an efficient fully automated common syngas generator for downstream synthesis units, such as ammonia and methanol synthesis, which can be designed for any size up to a total of 10.000 MTPD for a single SynCOR™. The concept allows for full conversion of the ammonia into urea.

Apart from methanol and ammonia production SynCOR Plus™ can also be used for a cost-effective production of Fisher Tropsch synthesis, carbon monoxide or hydrogen.