Knowledge & insights

Featured topics

By type

-

Featured

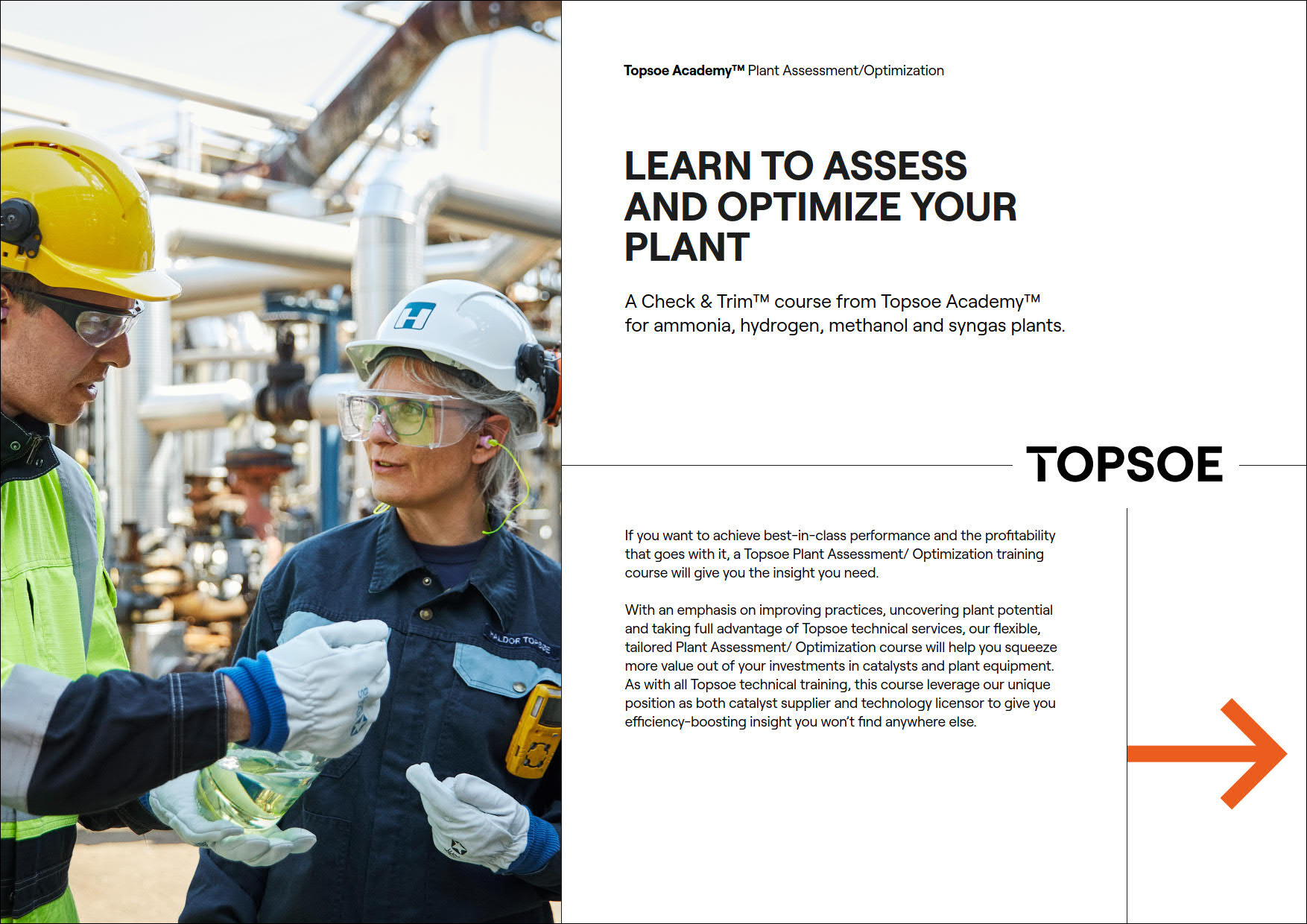

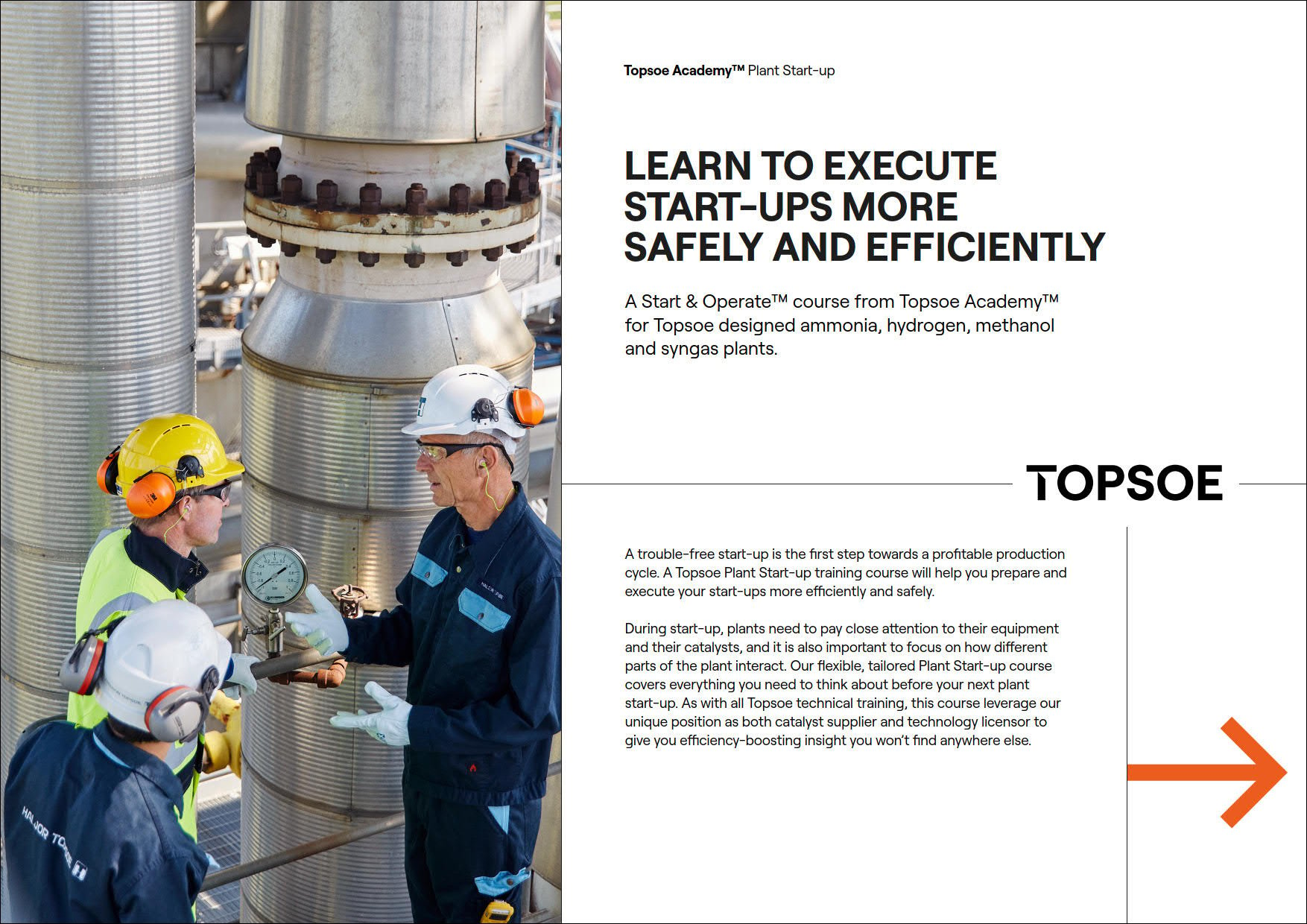

.png) Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more

Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more -

Discover how we meet the new energy reality to drive a sustainable future. Read

Discover how we meet the new energy reality to drive a sustainable future. Read

Solutions

Back

Solutions

Industries

-

Offerings

- Technologies

- Services

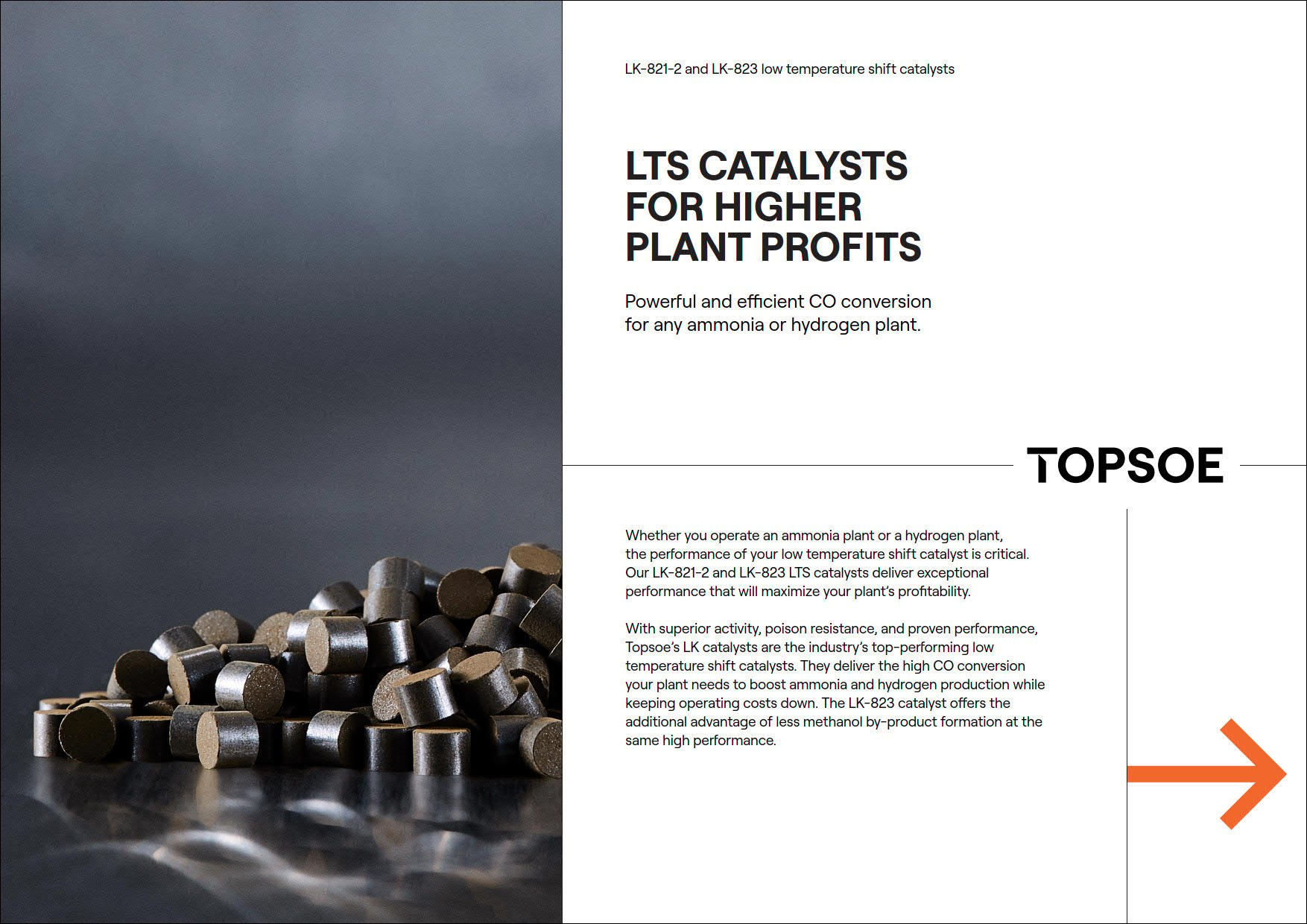

- Catalysts

- Power-to-X

News & events

Back

News & events

Careers

-

If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead

If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead

![[Re]Route to better energy featured Image](https://www.topsoe.com/hubfs/y2030201399_front-page.png)

.png)

.png)

.jpg)

.jpg)

.png)