TopFrax™ catalytic ceramic filter

TopFrax™ is a patent-pending catalyst-coated ceramic filter designed to treat off-gasses in high-dust environments found in a wide range of industries and activities.

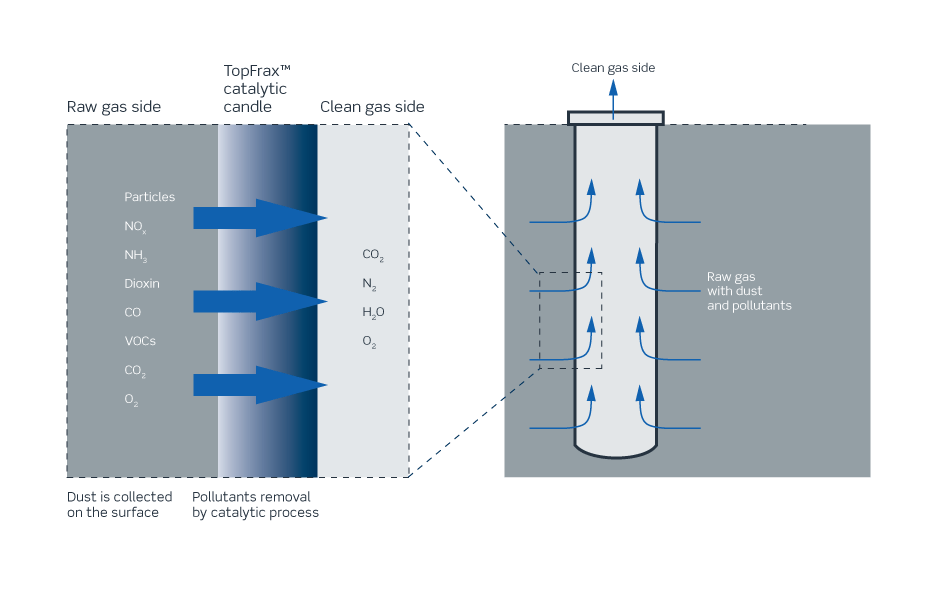

How TopFrax™ works

The TopFrax™ filter is based on a ceramic fiber impregnated with a particular catalytic solution. The chemical composition is made to suit the specific needs of the different customers. A combination of dust, NOX, NH3, dioxins, CO and different VOCs can be removed in one single step. The catalyst is loaded uniformly along a well-defined fraction of the wall providing the lowest cost of compliance and ensuring undesirable reactions (e.g. SO2 oxidation).

In addition to their multi-compound capabilities, TopFrax™ ceramic catalytic filters are effective at temperatures as high as 400°C. Combined, these advantages can help you reduce capital expenditures by up to 40% compared to competing solutions.

Broad spectrum of regulated pollutants

Built on decades of leadership in filtration and catalysis, TopFrax™ can transform the economics of meeting regulatory emissions standards, removing dust and multiple gaseous compounds in one single step.

Dust

TopFrax™ effectively blocks particulates and dust particles at the filter surface the same way conventional filters do, ensuring full compliance with stringent emission standards.

TopFrax™ candles are made from either refractory ceramics or fibers with low bio-persistence. Both products trap dust emissions (below PM 2.5) down to 2 mg/Nm3.

NOx

TopFrax™ use selective catalytic reduction (SCR) to remove NOx from off-gas, by utilizing ammonia to convert to harmless nitrogen and water.

VOCs

The catalyst sites on TopFrax™ filters also oxidize CO and volatile organic compounds into harmless CO2 and H2O.

The TopFrax™ oxidation version ensures optimal combustion of VOCs with no additional emission of CO.

Dioxins

TopFrax™ also ensures compliance with limits on dioxins and furans, by treating more than 99% of these by converting them into harmless compounds and reducing their concentrations to below 0.1 ng/Nm3, TEQ.

Reduce technology costs by up to 40%

As the only catalytic ceramic filter of its kind, TopFrax™ delivers entirely unique cost-saving benefits – saving up to 40% compared to separate DeNOx and oxidation technologies.

Other benefits include:

-

Simultaneous dust and multiple gaseous compounds removal in a single step

-

No need for costly, space-demanding tail-end gas removal equipment

-

Catalytic ceramic filter accommodates temperatures as high as 400°C (752°F)

-

No contact between catalyst and potentially harmful particles

-

Exceptional resistance to catalyst poisoning

-

Effective down to 180°C (356°F) operation

-

Easy to install and handle

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)