In the refining sector, the efficient production of middle distillates with improved cold flow properties is essential, particularly in regions exposed to severe cold weather conditions. A key challenge in this context is meeting the required cloud point specification of diesel fuels with minimal yield losses.

Cloud point is defined as the temperature at which wax crystals begin to form in the distillate fraction,1 impairing flow and compromising fuel quality. If the cloud point is too high, the fuel can become problematic in cold weather, leading to blockages in the fuel filters and compromised engine performance.

To address these challenges, Topsoe has developed a selective dewaxing catalyst TK-930 D-wax™ suitable for fossil feeds, co-processing and 100% renewable services. Engineered to perform under semi-sweet to fully sour conditions, the selective dewaxing TK-930 D-wax™ catalyst enhances hydrogenation and selectively targets paraffinic precursors responsible for high cloud points. The result is a significant improvement in cold flow properties without excessive cracking to lighter fraction, ensuring maximum preservation of the valuable distillate yields.

Chemistry of the dewaxing and cloud point improvement

Middle distillates such as diesel and kerosene/jet fuel often contain a high concentration of paraffins, particularly in streams with an elevated final boiling point. These paraffin-rich feedstocks are undesirable in finished commercialized fuels due to the mechanism by which they solidify at lower temperatures. Renewable feedstock is, by nature, rich in paraffins, which once hydrotreated requires cracking mechanisms to minimize the product cloud point or cold filter plugging point (CFPP).

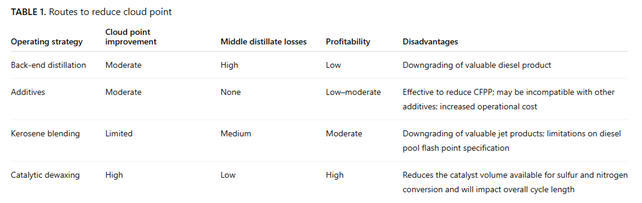

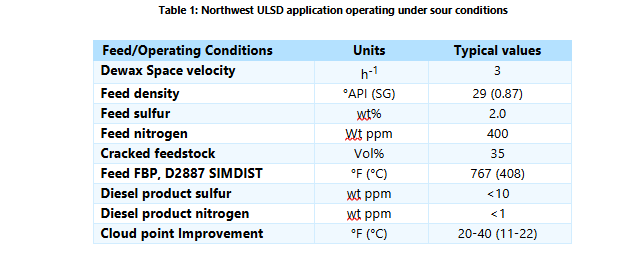

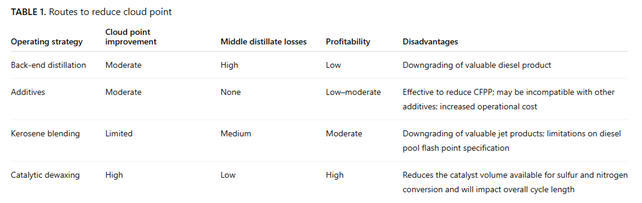

TABLE 1 provides information about methods to reduce product cloud point and summarizes the key technical and economic trade-offs among four common approaches to reduce the cloud point in middle distillates. Back-end distillation adjustment provides limited cloud point improvement and substantial distillate yield losses. For reference, a 36°F (20°C) reduction in backend distillation typically reduces the cloud point by 18°F (10°C)—delta T conversion. Additives provide moderate cold flow enhancement with operational flexibility, though they come with high recurring operating costs. Blending with kerosene offers a simple and immediate solution but reduces the volume of higher-value distillates, may compromise overall product pool value and only improves the cloud point by 2°F–4°F (1°C–2°C) by blending 8 vol%–12 vol% kerosene. In contrast, a dewaxing catalyst solution TK-930 D-wax™ delivers the most effective cloud point reduction with minimal distillate loss and high profitability, particularly when seamlessly integrated into existing hydroprocessing units as a bottom catalyst layer.

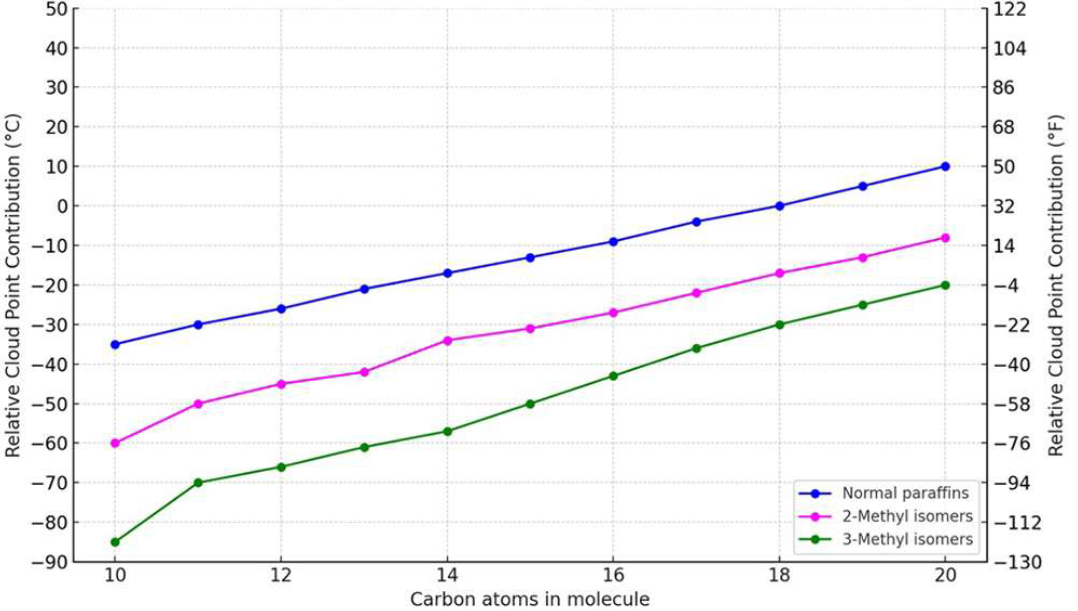

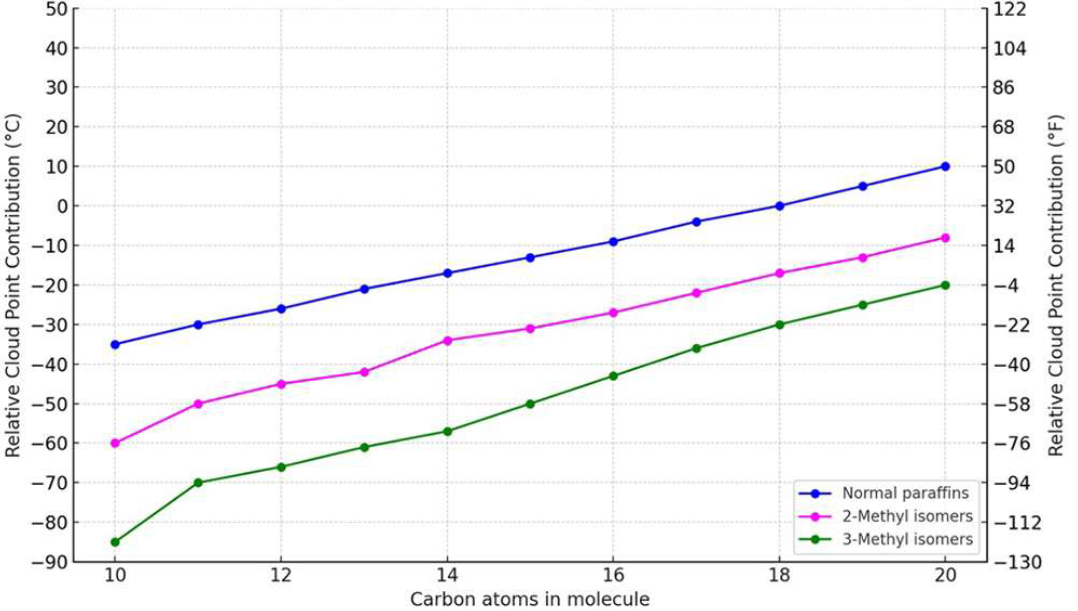

Dewaxing catalysts promote this molecular rearrangement, converting linear paraffins into branched isomers, thereby reducing the fuel’s cloud point without cracking the molecules into lighter products, as observed in FIG. 1. This approach allows refiners to improve cold flow properties while preserving middle distillate yields, offering a more selective and efficient alternative to conventional dewaxing. However, improper zeolite formulations can lead to significant cracking functionality, reducing overall product yield and margin. In a fossil unit, there is also a reduction in T90, which allows refineries to increase the feed endpoint while still meeting the maximum T90 (D86) diesel specification. This additional benefit enables the refinery to increase diesel production, making dewaxing just as profitable in both summer and winter modes.

FIG. 1. Branching paraffins and cloud point improvement.

FIG. 1 illustrates the relative cloud point contribution of different paraffinic isomers. Normal paraffins exhibit significantly higher solidification temperatures, contributing heavily to cloud point deterioration. In contrast, 2-methyl and 3-methyl isomers have much lower crystallization tendencies, making them far less likely to precipitate as wax at low temperatures.

Challenges during dewaxing operation

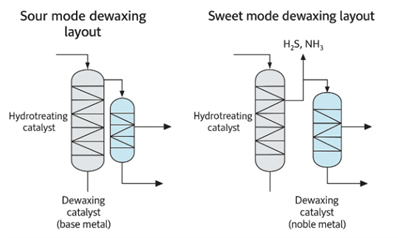

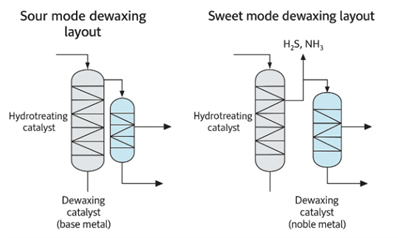

When implementing a dewaxing solution, conventional fossil hydrotreaters often operate in a single-stage configuration, which means the dewaxing catalyst is exposed to the same conditions as the hydrotreating catalyst. In feedstocks with high sulfur and nitrogen content, the resulting hydrogen sulfide (H2S) and ammonia (NH3) or organic sulfur and nitrogen compounds can significantly inhibit the performance of conventional dewaxing catalysts. In such cases, some units may need to operate in sweet mode to achieve the desired level of isomerization.

In renewable applications, water formation is a natural byproduct of the reaction, and this environment can also significantly impact catalyst performance.

As illustrated in FIG. 2, the key difference between sour and sweet mode dewaxing lies in the operation of an interstage stripper in sweet mode. This stripper removes H2S and NH3 before the second stage, preventing inhibition of the hydrogenation and isomerization pathways typically facilitated by noble metal catalysts.

FIG. 2. Topsoe dewaxing configuration: Sweet vs. sour mode.

The innovation of the dewaxing catalyst solution TK-930 D-wax™

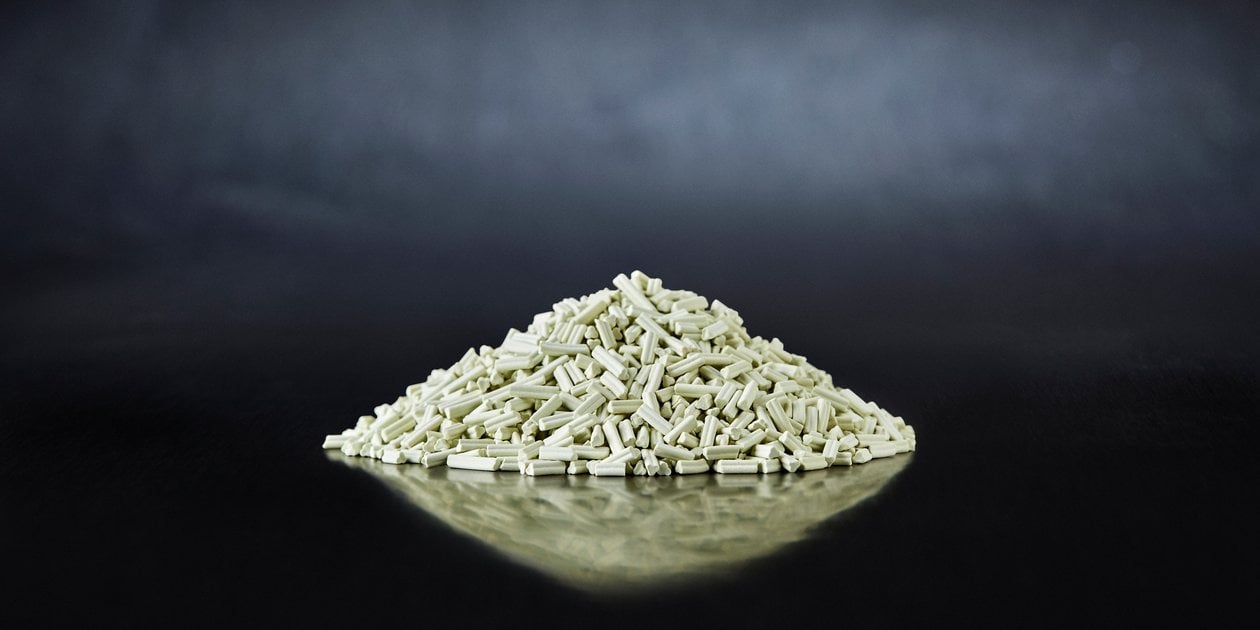

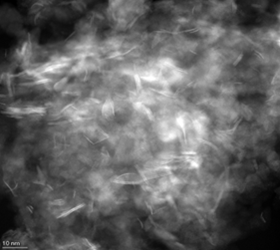

Topsoe’s specialized zeolite-based TK-930 D-wax™ (shown in FIG. 3) was developed to operate under semi-sweet to fully sour conditions. It improves the cold flow properties by isomerization, keeping the same number of carbon atoms in the molecule. This minimizes yield loss to lower boiling fractions.

FIG. 3. Topsoe specialized zeolite-based TK-930 D-wax™.

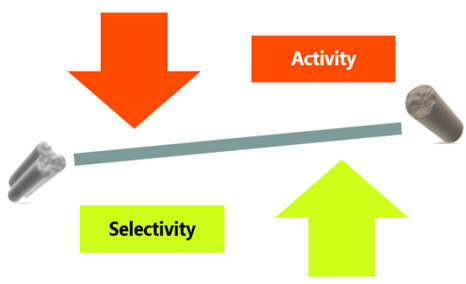

Topsoe’s selective TK-930 D-wax™ catalyst, promoted by base metals, enables refineries to adopt a drop-in solution for existing hydrotreaters. Another key feature is its good hydrogenation activity, thereby enabling the TK-930 D-wax™ catalyst to also help meet product sulfur specifications and saturate aromatics for additional volume swell. Furthermore, the metals (FIG. 4) will ensure good stability of the catalyst as the hydrogenation functionality reduces coking and deactivation.

FIG. 4. High dispersed metal slabs in our TK-930 D-wax™ catalyst.

The zeolite-based selective TK-930 D-wax™ catalyst resists inhibition from water, organic sulfur and nitrogen as well as H2S and NH3, ensuring consistent performance while minimizing undesired byproduct formation. The zeolite structure also functions as a molecular sieve, selectively allowing long-chain n-paraffins to undergo isomerization. These key features are explained below.

Minimizing distillate yield loss

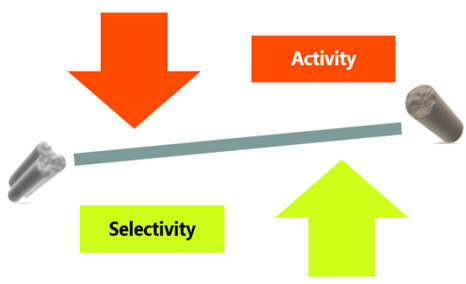

The structure of the selective TK-930 D-wax™ catalyst enables efficient and selective dewaxing. The zeolite features acid sites within a special porous distribution framework, forming channels that are critical for optimizing catalyst activity and selectivity. The size and geometry of these channels enhance accessibility to the active sites, ensuring that even under sour conditions, paraffins are isomerized effectively, minimizing hydrogen (H2) consumption (favoring isomerization vs. cracking) and limiting middle distillate yield loss.

FIG. 5. Optimized zeolite: Balancing accessibility and selectivity.

High water, sulfur and nitrogen tolerance

The TK-930 D-wax™ catalyst is specifically engineered to resist the inhibiting effects of water, sulfur, nitrogen and other contaminants commonly found in fossil and renewable feedstock. This high tolerance has been validated through extensive commercial experience, demonstrating long-term catalyst stability and consistent performance throughout the cycle.

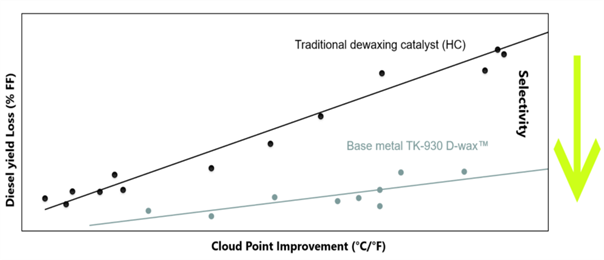

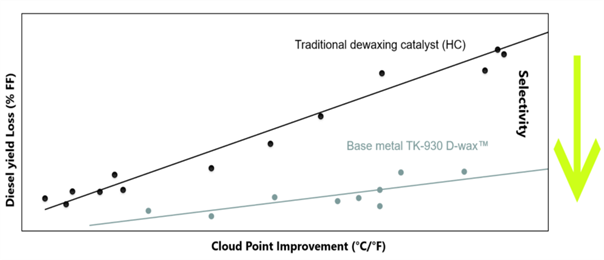

FIG. 6 shows that the proprietary TK-930 D-wax™ catalyst reduces the diesel yield loss significantly compared to conventional dewaxing catalysts.

Demonstrated flexibility and performance in commercial units

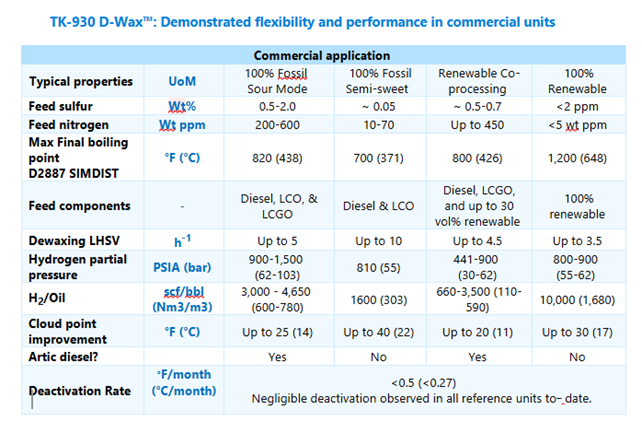

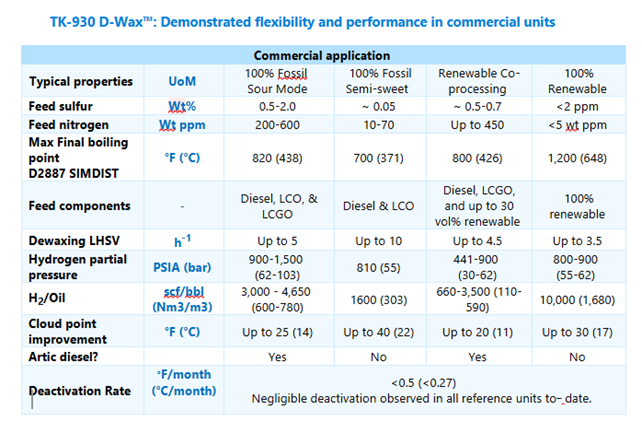

The versatility of Topsoe’s TK-930 D-wax™ has been commercially demonstrated across a broad range of applications, from high-sulfur fossil feeds to 100% renewable feedstocks. It delivers stable performance under diverse operating conditions, including wide variations in feed sulfur and nitrogen content, boiling points, water formation, H2 partial pressure and H₂-to-oil ratios. Topsoe’s TK-930 D-wax™ achieves significant cloud point improvements while maintaining low deactivation rates across all service conditions, including arctic diesel production. Its ability to contribute to hydrodesulfurization (HDS) and hydrodenitrogenation (HDN) activity, even under severe or renewable processing environments, makes it an optimal choice for grassroots units and existing fossil diesel units.

Stability is another critical performance metric to consider when choosing a dewaxing catalyst. For our TK-930 D-wax™, minimal deactivation has been observed across all of our dewaxing applications, as shown in TABLE 2, delivering a strong return on investment over the cycle.

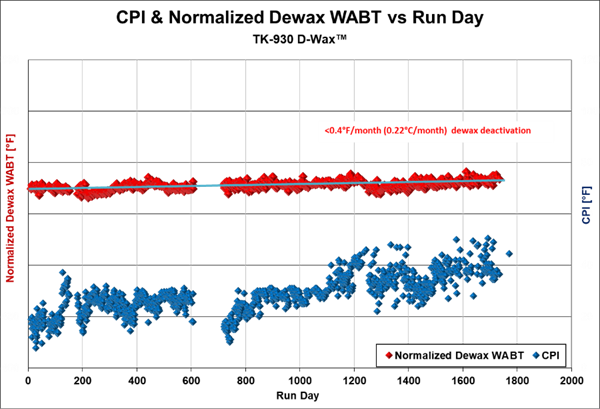

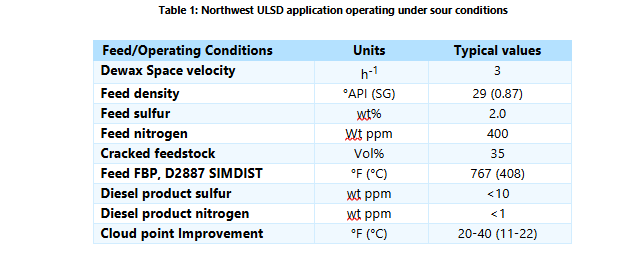

TABLE 3 below shows the operating condition of a fossil-fuel ultra-low sulfur diesel (ULSD) unit with the proprietary TK-930 D-wax™ for cloud point adjustment.

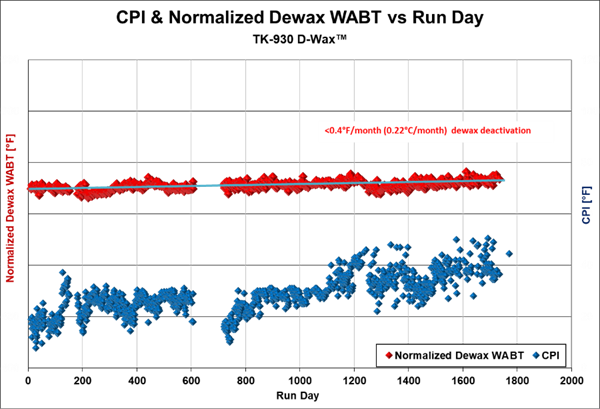

The plot (FIG. 7) illustrates the long-cycle stability of Topsoe’s TK-930 D-wax™ in sour service. The red trend represents the normalized dewaxing weighted average bed temperature (WABT), while the blue trend shows the cloud point improvement across 1,800 run days (~5 yr).

Despite prolonged operation under challenging conditions, the catalyst demonstrates exceptional stability, with a dewax deactivation rate of < 0.4°F/mos (< 0.22°C/mos).

FIG. 7. Catalyst stability in a commercial unit for a > 6-yr run.

Takeaway

Our TK-930 D-wax™ dewaxing catalyst sets a new benchmark in dewaxing performance under both fossil and renewable fuel services. Designed to excel in sour and semi-sweet conditions, the TK-930 D-wax™ combines high isomerization activity with robust water, sulfur and nitrogen tolerance, delivering outstanding cloud point reduction while minimizing yield loss.

Unlike traditional dewaxing technologies that often compromise distillate yield or require layout modifications, TK-930 D-wax™ operates effectively within existing unit configurations. Its proven ability to maintain stability over long cycles, even under severe feed conditions, provides refiners with a cost-effective and operationally flexible solution. The TK-930 D-wax™ catalyst enables higher feed endpoints while maintaining T90 diesel specifications, maximizing diesel production and profitability.

With the industry’s growing demand for ULSD, renewable diesel and seasonal arctic fuel grades, the dewaxing catalyst empowers refiners to maximize unit profitability year-round. Whether in grassroots installations or existing fossil units, its versatility and reliability unlock full dewaxing potential, without the trade-offs.

The original version of this article was first published by Hydrocarbon Processing magazine. It is reprinted, with minor edits, with their kind permission.

.png) Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more

Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more Discover how we meet the new energy reality to drive a sustainable future. Read

Discover how we meet the new energy reality to drive a sustainable future. Read If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead

If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead