Vapor Lift Distributor Tray

Our Vapor Lift Distributor Tray (VLT) ensures uniform distribution of liquid and gas over the entire cross section area of the catalyst bed.

The tray is equipped with an unmatched number of dripping points, enabling uniform wetting of the catalyst below.

Our Box VLT consists of a self-supportive structure, which both renders beams obsolete and diminishes tray deflexion. The absence of support beams also allows for increased catalyst loading and a consequently higher efficiency.

Installation

The VLT distributor tray’s construction is based on modular principles, with the number of modules optimized and customized for each reactor. Modules are “match-marked” for simple assembly and easy installation.

The VLT is equipped with our Quick-Release™ fasteners for speedy installation and dismantling and easy manway access. In addition, the number of bolted connections has been minimized to eliminate problems with seizing and to reduce overall installation time.

|

|

| Installation point of the Vapor Lift Distributor Tray (VLT) | Installation point of the Vapor Lift Distributor Tray (VLT) and Scale Catcher |

Scale catching capacity

Our VLT distributor tray has the capacity to accommodate a large number of scales and particles without compromising gas and liquid transfer and distribution to the catalyst bed below.

In services where the amount of scales and particles introduced during the cycle is expected to exceed the VLT’s scale catching capacity, we recommend installing our Liquid Phase Scale Catcher.

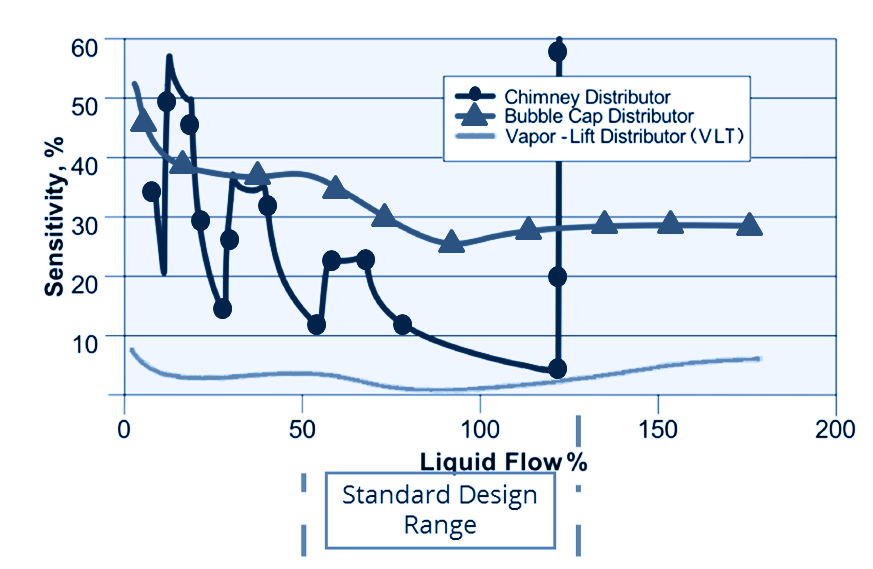

Sensitivity

Our VLT is proven to display the lowest sensitivity to changes in process conditions. Stabilities of different distributor types are shown here:

Quality Control

All trays are preassembled in the workshop to ensure that you receive high-quality products.

“Leak proof” testing can be conducted in our workshops on request.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)