Value-adding custom solutions for your business

Sour refinery off-gasses contain hydrogen sulfide (H2S). H2S poses a danger to human health and is harmful to the environment.

Topsoe customizes amine regeneration units that absorb and eliminate the risk of these off-gasses.

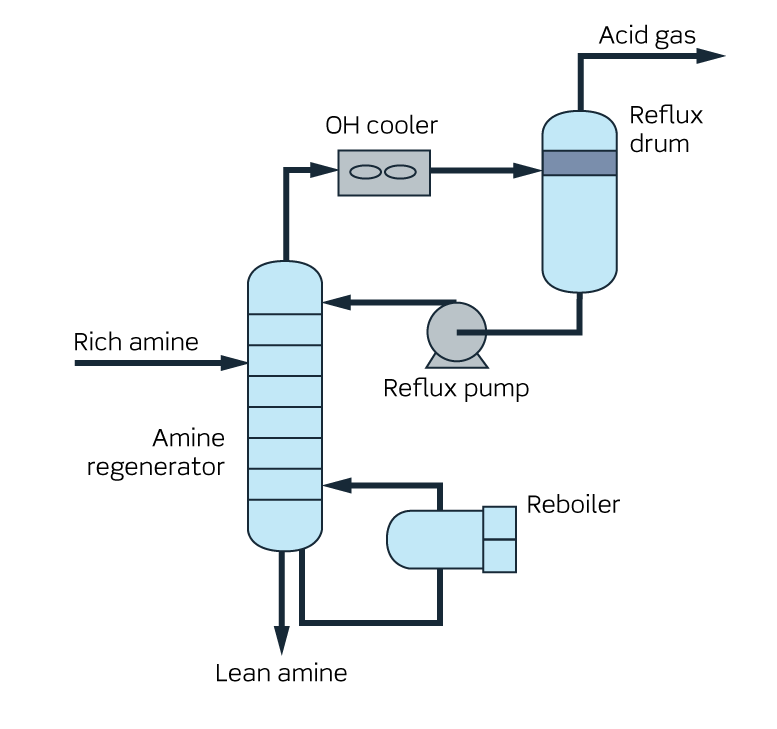

When hydroprocessing units convert organic sulfur compounds into H2S, the H2S ends up in the sour off-gas for removal by absorption in an amine scrubber. The result is H2S enriched amine, which is pumped to the top of the amine regenerator column. Here, it is counter-currently contacted with hot vapor from the amine regenerator reboiler at the bottom of the column. The H2S is then stripped off and recovered from the top of the column, while lean amine with equilibrium amounts of H2S is recovered from the bottom. Reflux water is fed into the top of the column to absorb any amine carry-over in the rectification section. Topsoe amine regeneration prevents amine losses into the overhead and effectively removes all H2S.

Topsoe works closely with customers to purpose-design amine regeneration units to fit their operational goals.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)