Improve color and extend cycle lengths

Refiners increase reactor-operating temperatures during a typical reactor cycle to meet the HDS specification.

The problem is that increased temperatures have a negative impact on aromatic saturation. Failure to saturate aromatics can result in product coloration and shorter cycle lengths. Topsoe Polyshift™ technology offers a simple solution to these problems.

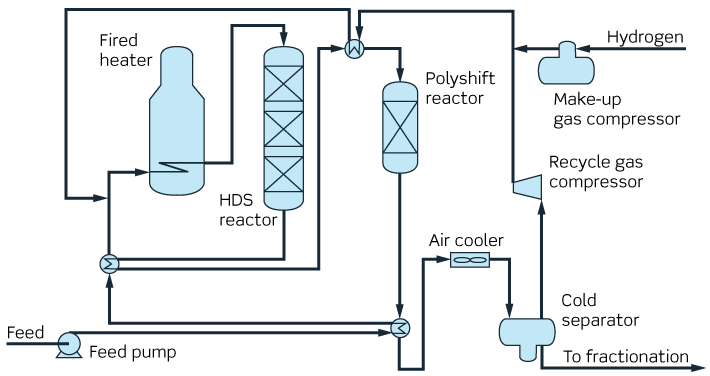

You can install the Polyshift™ reactor downstream from the HDS reactor in a hydrotreating configuration, which operates at a lower temperature to improve color and increase cycle lengths.

The Polyshift™ technology is effective, even if your refinery has a limited hydrogen supply. The process operates at elevated temperatures that reverse the aromatic saturation and liberate hydrogen. The hydrogen can then be recycled into the HDS reactor, enabling operations to process more feed.

While the process may reduce cetane improvement and volume swell, our Polyshift™ licensed technology improves color to meet the most stringent specifications.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)