The application of ammonia cracking is versatile. It can be centralized and implemented on large to mega-scale, with the production hydrogen then transported to its end-use location via a comprehensive hydrogen grid, as currently planned in Europe.

Alternatively, it can be deployed in a decentralized, large-scale manner, located near major hydrogen consumers, potentially through local hydrogen grids.

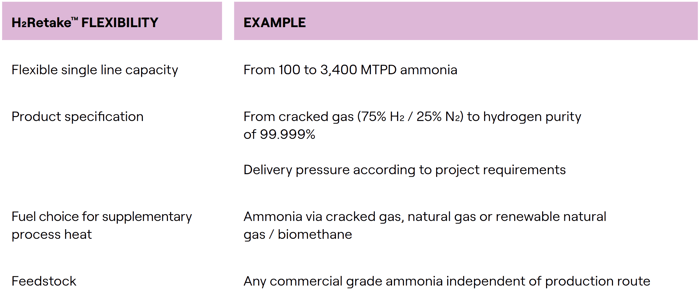

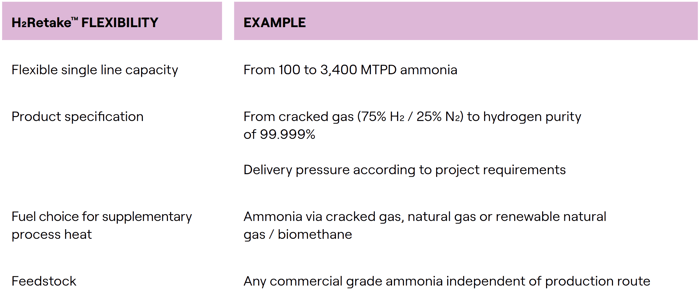

H2Retake™ provides a versatile approach in its scale and deployment, allowing companies flexibility regarding ammonia cracking capabilities. So, from decentralized off-take dedicated ammonia crackers to largescale centralized ammonia crackers feeding hydrogen grids, our ammonia cracking set-up can be adapted to feed your requirements.

Proven large-scale ammonia cracking

We have the only industrially proven ammonia cracking technology available and optimized to perform exceptionally well under ammonia cracking conditions.

Largest reference plant: Arroyito, argentina

Our largest plant in Arroyito, Argentina, with a capacity of up to 2 X 2,400 MTPD in two parallel lines, is a testament to our proven technology.

The core components of H2RetakeTM, catalyst technology, and supporting solutions put us in a unique market position to deliver process and catalyst guarantees.

Delve into the H2RETAKE process

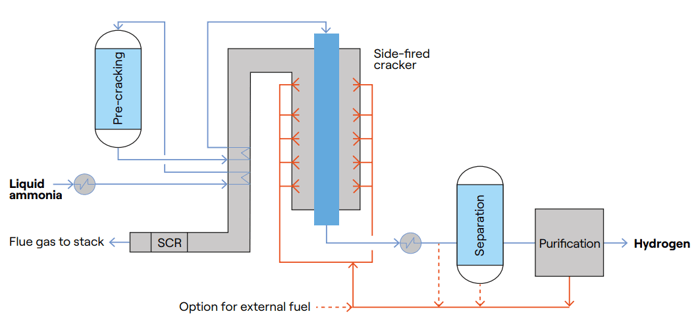

The core H2Retake builds on our established side-fired cracking technology. Despite overall similarities in the design with conventional steam methane reformers, H2Retake primarily differs in the choice of equipment materials, as these must tolerate harsh nitridation conditions in the ammonia cracker, and of course the catalyst.

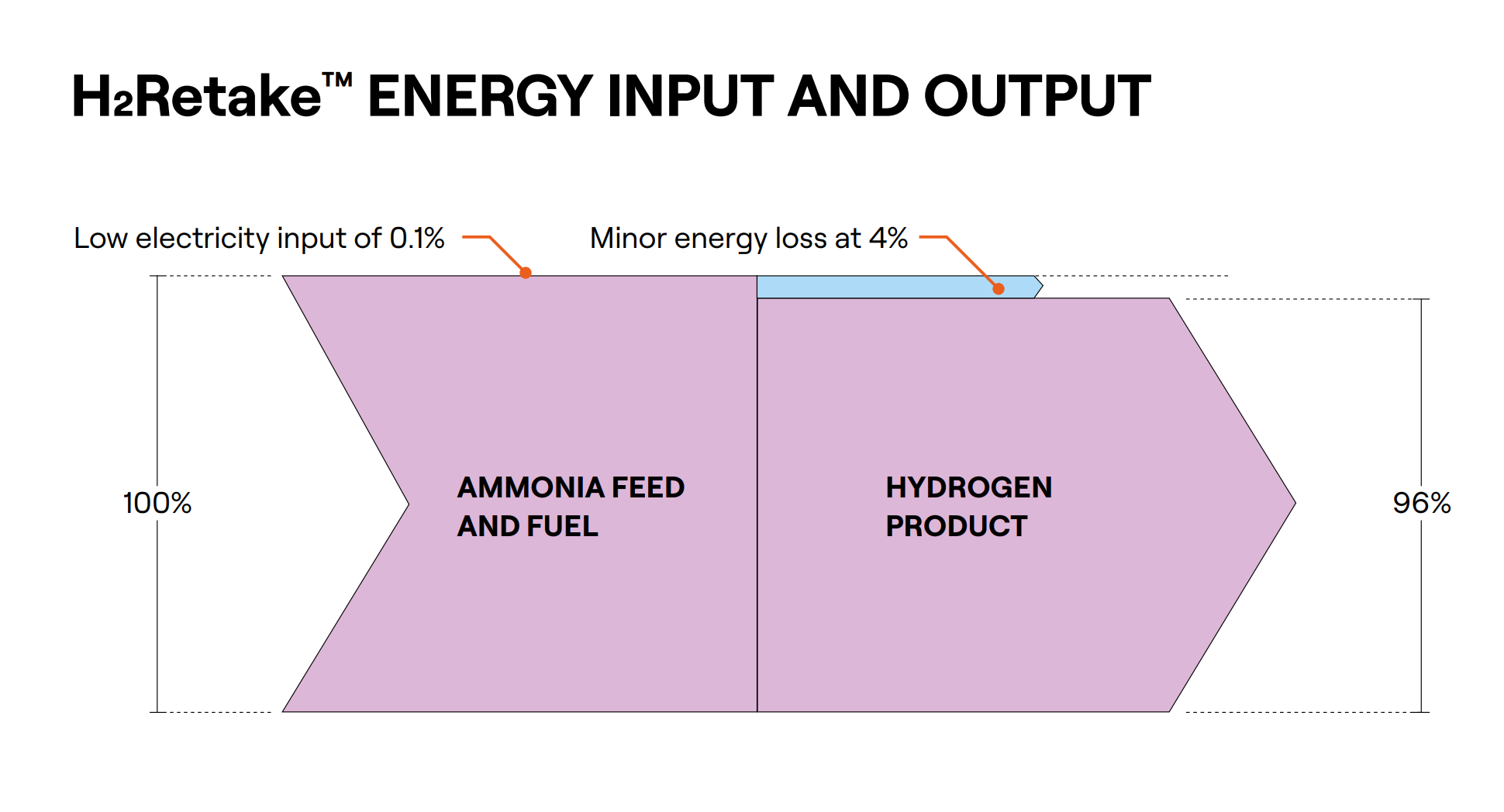

H2Retake improves the overall ammonia cracking performance with high conversion rates, energy optimization, catalyst selection, process integration, and advanced technologies to ensure the most efficient pathway to a cost-efficient, large-scale clean hydrogen supply.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)