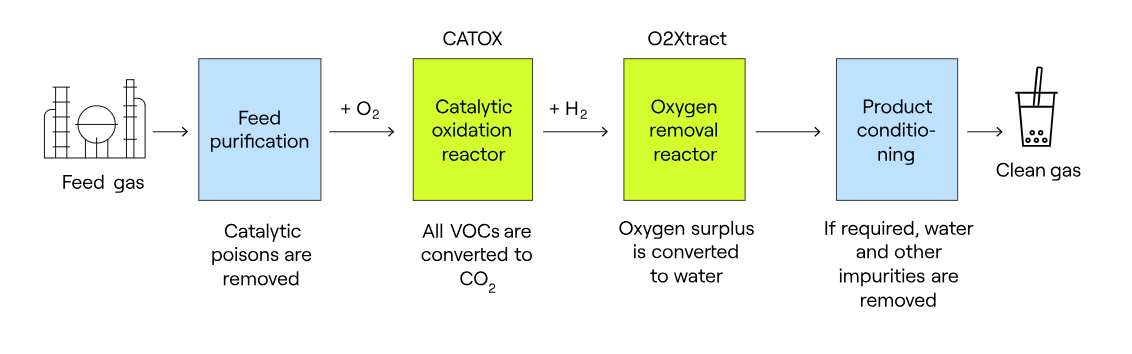

We have developed a two-step catalytic system for maximum purity made up of two of our advanced technologies.

In step 1, the CATOX™ catalytic oxidation technology efficiently uses oxygen to remove volatile organic compounds (VOCs) and other impurities such as hydrogen, carbon monoxide, and ammonia.

In step 2, any surplus oxygen introduced during this first step, can be removed upon dosed hydrogen addition with the O2Xtract™ – a catalytic solution designed to efficiently and cost-effectively eliminate trace oxygen from gas streams, ensuring the production of high-purity gases and compliance with the most stringent industry standards.

.png)

.png?width=800&height=640&name=Wind_turbines_on_field%201%20(1).png)