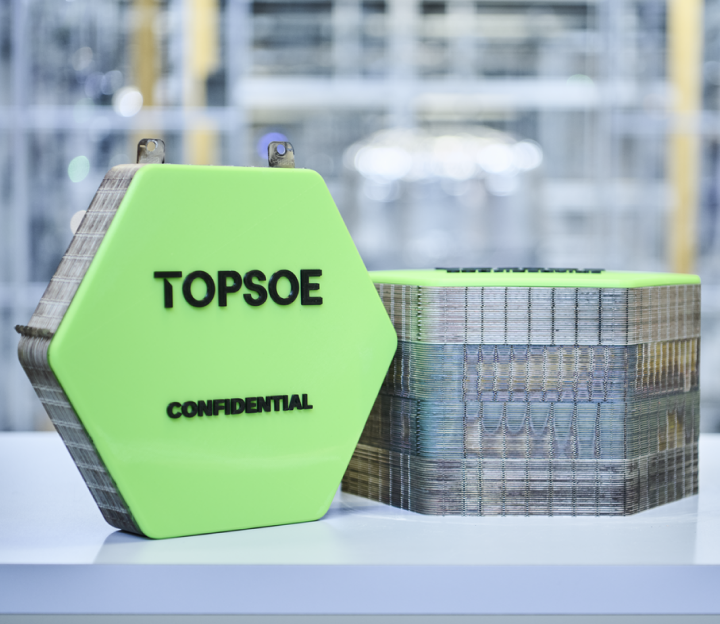

Solid Oxide Electrolysis

Explore the benefits of high-efficiency SOEC

Visit our new SOEC page to learn how this high-temperature electrolysis technology uses renewable energy to convert water into hydrogen and oxygen without emissions, supporting a cleaner energy future.