High-Performance Burner Design for Reliable Reformer Operation

The CTS™ (Cool Tip Swirl) burner is a crucial piece of equipment, and its importance in reformer reliability and availability cannot be underestimated. Good burner performance is characterized by:

-

Short and centralized flame

-

Low metal temperatures on burner nozzles

-

Soot-free operation

-

Easy operation

-

Long lifetime

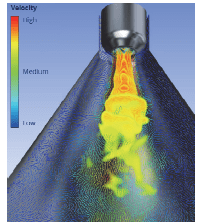

Under the challenging operating conditions of the autothermal reformer, a poorly designed burner can lead to unsatisfactory equipment lifetime and unsafe operation. For example, because the fuel-rich combustion takes place in a turbulent diffusion flame, thorough mixing is essential to avoid soot formation. The flame core can exceed 3,000°C, which means it is also essential to minimize heat transfer from the flame and hot gas recirculation to the burner nozzles.

The Topsoe CTS™ burner has been optimized to achieve the features listed above and to provide proper mixing of the oxidant and hydrocarbon feeds. With the CTS™ burner, the process gas is well mixed and evenly distributed before it enters into the target tile layer and the catalyst bed, resulting in good catalyst performance and high runtime between maintenance stops.

Topsoe CTS™ burners have been in operation in oxygen-fired secondary reformers and SynCOR™ units for decades with high reliability and outstanding safety records. Topsoe SynCOR™ reformers have accumulated more than 70 years of Industrial safe operation at a low S/C ratio of 0.6. We use this experience to continuously improve the burner in order to meet wider ranges of operating conditions, such as lower S/C ratios at increased capacities.

In recent years, Topsoe introduced a new-generation CTS™ burner. Main features of the new-generation CTS™ burner is the flow-optimized burner nozzle, the use of alloys with high-temperature stability, and the use of enhanced nozzle cooling. These features make the Topsoe CTS™ burner suitable for very large single-line capacities in Topsoe SynCOR™ operating at S/C ratios of 0.6 and below. The new-generation CTS™ burner has been in operation for over six years in large-scale industrial SynCOR™ units converting more than 180,000 Nm3/hr of natural gas.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)