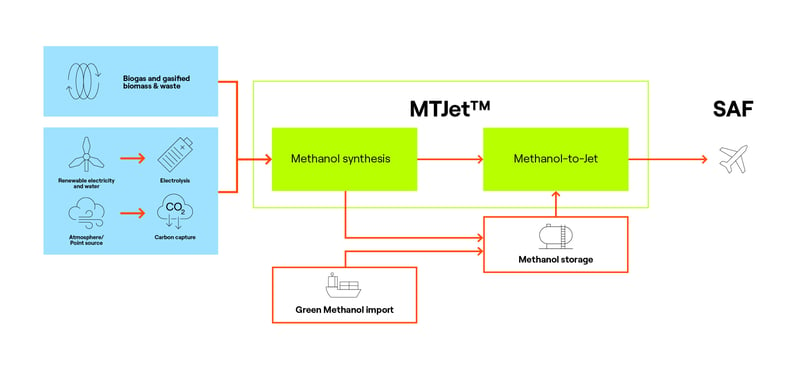

With Sustainable aviation fuels (SAF) taking off, producers need a robust pathway that can help future-proof their business while simultaneously generating operational stability around the clock. The MTJet™ solution offers just that. Utilizing methanol as an intermediate for jet fuel synthesis allows producers to handle and capitalize on a dynamic range of situations and feedstocks.

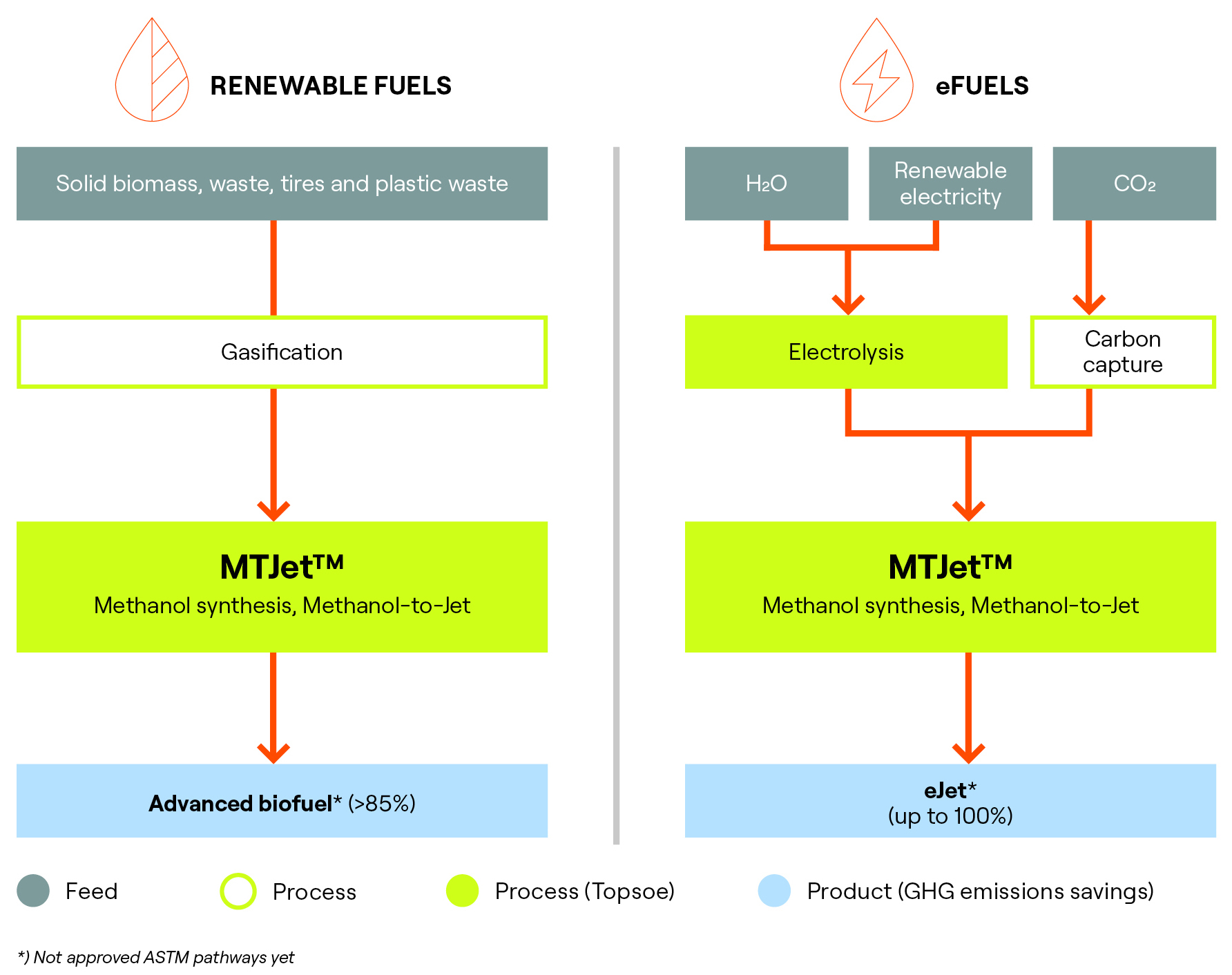

Our MTJet™ technology is based on years of commercial experience and internal research and development within methanol synthesis and methane-rich gas-to-gasoline processes – TIGAS™. The result is a methanol-to-jet solution that can deliver eJet fuel from renewable electricity, water, and CO2 or advanced biofuel from solid biomass feedstocks. Creating a truly end-to-end– feedstock to jet fuel out product.

.png)

![SAF Airplane runway[1]-1 1](https://www.topsoe.com/hs-fs/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)