By rewriting the book on ammonia plant capacities, SynCOR Ammonia™ enables greater economies of scale and paves the way for new benchmarks, new financials and new opportunities – all using proven technologies.

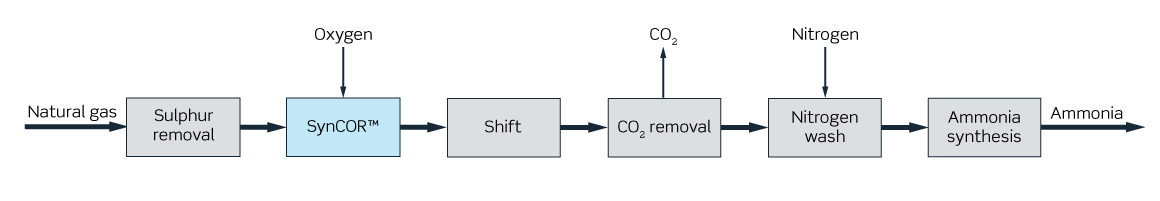

SynCOR Ammonia™ is a technology break-through in the ammonia industry. Where all ammonia plants today rely on conventional two-step reforming based on tubular steam methane reforming and an air-fired secondary reformer, SynCOR Ammonia™ utilizes the unique Topsoe SynCOR™ solution, a process based on oxygen-fired autothermal reforming.

SynCOR Ammonia™ introduces a previously unseen scaling factor for single-train ammonia plants, thanks to a steam-to-carbon ratio of just 0.6 – reducing steam throughput by 80%. The result can be double-digit reductions in the cost per ton of producing ammonia – with greater savings achieved the further you scale up.

By introducing new economies of scale into ammonia production, SynCOR Ammonia™ gives plant owners breakthrough options for profitable expansion and provides new investors with an opportunity to enter the market with a sharp competitive edge.

Simplified process layout

.png)

.png)

![SAF Airplane runway[1]-1 1](https://2115834.fs1.hubspotusercontent-na1.net/hub/2115834/hubfs/SAF%20Airplane%20runway%5B1%5D-1%201.png?width=800&height=640&name=SAF%20Airplane%20runway%5B1%5D-1%201.png)