eREACT™ Hydrogen: The future of blue hydrogen

Electrify your production for ultra-low carbon intensity

As the world moves to decarbonize, there remains the question of whether fossil feedstocks can still fulfill a role consistent with the net carbon zero journey. Fortunately for producers, the answer is yes: TOPSOE™'s eREACTTM Hydrogen technology is the electrified evolution of the world’s most common hydrogen-production method, steam-methane reforming. It allows producers to leverage their existing hydrocarbon infrastructure while seamlessly integrating (renewable) power into their production - and providing real support for the global energy transition.

While SMR typically generates needed heat through combustion of natural gas - which results in CO2 emissions - eREACTTM Hydrogen facilitates the same reaction without the associated environmental impact. The reaction heat for eREACTTM Hydrogen is generated directly by renewable electricity eliminating thereby the flue gas altogether. With the cost of renewable electricity decreasing rapidly, this groundbreaking technology empowers even existing industrial complexes to electrify their hydrogen production in a cost-effective manner.

Some of the eREACTTM Hydrogen technology benefits are

-

Simpler plant design – no flue gas section

-

Eliminate all flue-gas from your hydrogen-production process

-

Operate at ultra-low carbon intensity (0-0.2 Kg CO2/kg H2)

-

Easier operation – fuel mix and burner control are replaced with power control

-

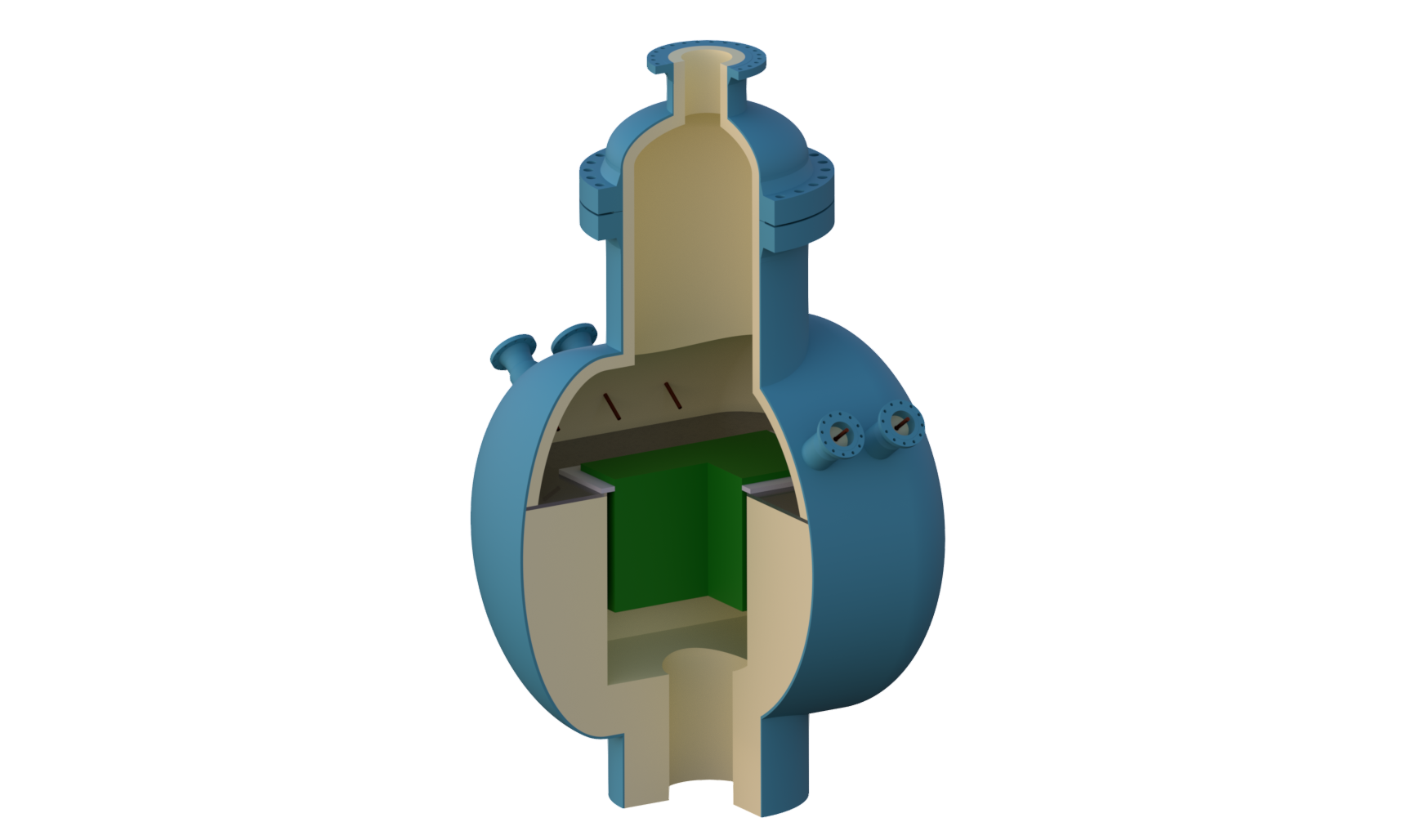

Minimize your plant footprint with a solution 100x smaller than a traditional SMR furnace

-

Improve energy efficiency

-

Utilize 4-5 times less electricity than a comparable electrolysis operation

View our latest update from our eREACT™ plant.

Learn more about how eREACTTM Hydrogen technology can transform your hydrogen operation when you get in touch with our experts.