As a multipurpose, low carbon product that is increasingly being seen as gamechanger in decarbonizing shipping, agriculture and several other key industries, green ammonia is showing all the signs of exponential market growth.

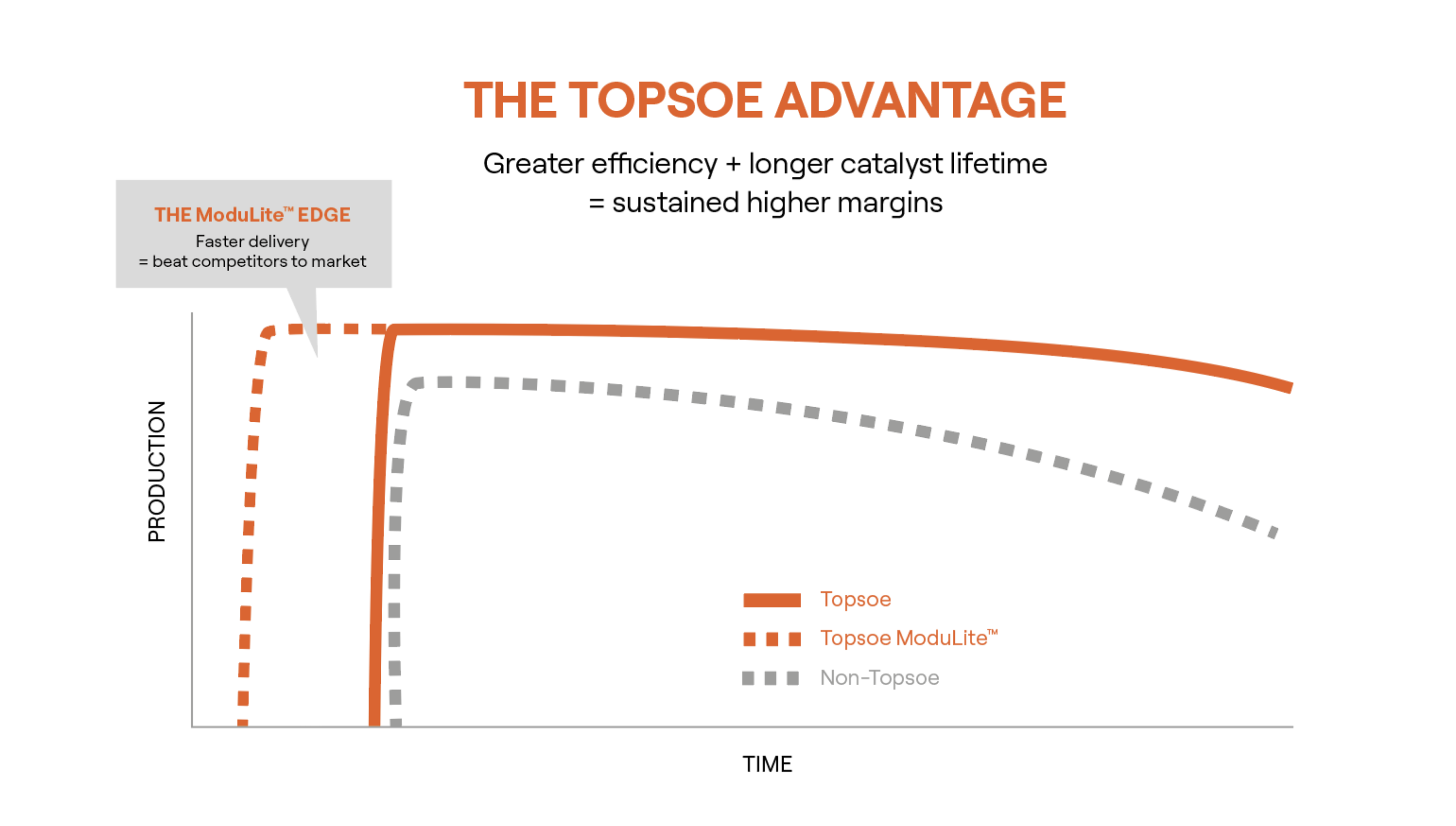

To meet this projected demand and further the green energy transition, it is vital that green ammonia production proves to be sustainable and profitable – and this all comes down to the quality of your ammonia loop.

By maintaining outstanding performance throughout its lifecycle, the right ammonia loop can overcome the complexity involved in synthesizing ammonia from nitrogen and green hydrogen, and become the backbone of a profitable green ammonia plant. This is why your choice of ammonia partner is critical for success.

With nearly a century of leadership in ammonia production, Topsoe has the knowledge, experience and solutions it takes to succeed with green ammonia.

Knowledge & insights

Featured topics

By type

-

Featured

.png) Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more

Topsoe Academy™ Topsoe Academy™ is your chance to tap into over 80 years of accumulated knowledge Find out more -

Discover how we meet the new energy reality to drive a sustainable future. Read

Discover how we meet the new energy reality to drive a sustainable future. Read

Solutions

Back

Solutions

Industries

-

Offerings

- Technologies

- Services

- Catalysts

- Power-to-X

News & events

Back

News & events

Careers

-

If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead

If you’re ready to work alongside inspiring people like Hadise, Go solve at Topsoe.A place to make an impactRead